One of the most significant challenges in the past years faced by the global electronics sector was the semiconductor shortage, or “Chip Crisis.” This major disruption, caused by a combination of pandemic-related demand shifts, geopolitical tensions, and manufacturing bottlenecks, has had a far-reaching impact on the whole electronics supply chain. The result was a chain reaction of production delays, rising costs, and huge pressures on logistics networks trying to cope with the very unstable inventory and fulfilment processes.

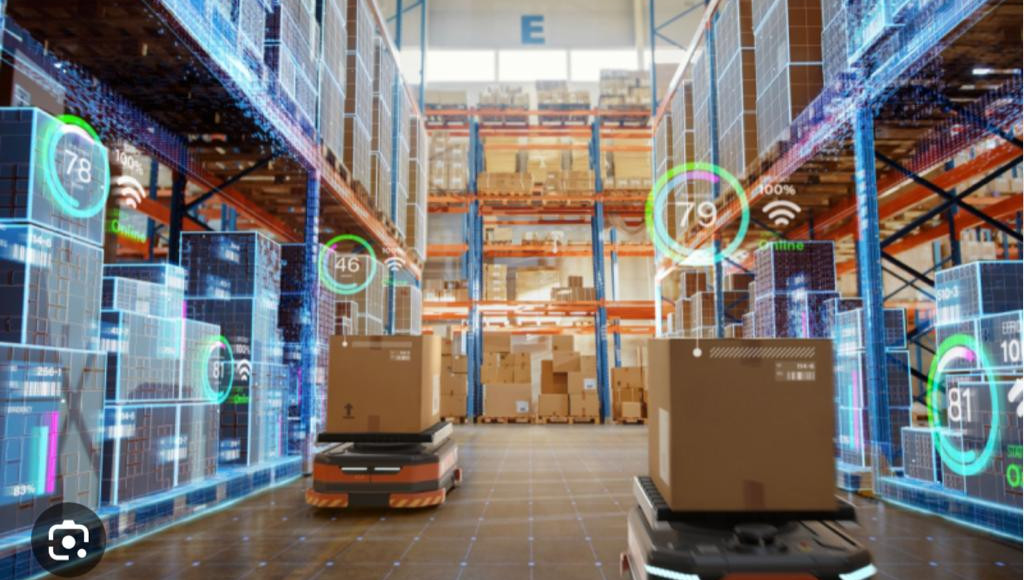

In today’s world of limited resources and unpredictable events, warehouses have changed their purpose. They’re no longer just places to store things; they are strategic hubs where resilience, visibility, and speed are manufactured. The main tool that’s making this change possible is the warehouse management system. It’s new features that help solve the problems caused by the Chip Crisis.

The Challenge: Volatility and Scarcity in Electronics Logistics

The shortage of computer chips created unique supply chain issues that standard ways of operation couldn’t handle:

- Extreme Volatility in Component Supply: Electronics manufacturers began to receive components in small, irregular, and unpredictable batches (called “dribble-feed” logistics). This made it almost impossible to plan production runs, changing inventory control from a steady flow to a constant struggle.

- Increased Value and Security Risk: As chips and components became scarce, their cash value shot up. This meant companies needed to tighten security measures, keep more detailed records, and handle high-value components with special care.

- Complex Prioritisation and Allocation: Warehouses had to choose which production lines or customer orders received the scarce components because they didn’t have enough stock to fill all orders. This process is called allocation. It needed detailed, up-to-date info on where stock was, how much there was, and its quality (like specific batch numbers).

- Expedited Handling of Critical Shipments: Getting scarce parts to the production line was so urgent that usual FIFO (First-In, First-Out) methods often got tossed aside. Instead, they gave priority to certain incoming and outgoing shipments (LIFO, or Last-In, First-Out, for vital materials).

The Solution: Leveraging Advanced WMS Features

A cutting-edge, robust warehouse management system serves as the tech backbone to turn these tricky challenges into streamlined, fine-tuned processes. The standout feature that tackles the ups and downs of the Chip Crisis is Highly Granular Inventory Tracking and Allocation.

- Highly Granular Inventory Tracking and Allocation.

For pricey electronics parts, keeping tabs at the pallet or even case level just doesn’t cut it. A state-of-the-art warehouse management system backs item-by-item and serial number tracking using tech like RFID or advanced barcode scanning integrated with the system.

- Serialised Tracking (Lot/Batch Control): The warehouse management system keeps a record of not just the amount but also the unique serial number, batch number, vendor, and expiration date for every key component. This plays a vital role in quality control (recalls) and, for prioritised allocation.

- Real-Time Location Mapping: Using tech like RTLS (Real-Time Locating Systems) or basic zone/shelf mapping, the warehouse management system knows the exact spot where every valuable item is, cutting down search time—a key factor when a part is needed in production.

- Dynamic, Rules-Based Allocation (The Brain of the Crisis Response)

When there’s a shortage, the warehouse management system takes on the role of a central brain, figuring out where to send the few chips available. This happens through flexible, rules-based distribution often called “Smart Allocation.”

- Prioritisation Engine: The warehouse management system combines information from the order management system and enterprise resource planning to figure out which manufacturing orders matter most (for example, those with the highest value, nearest deadline, or most important customer). It can then assign incoming limited inventory to these specific top-priority work orders before any others.

- Hard vs. Soft Allocation: The system lets you do hard allocation (setting aside a specific batch of components for a specific work order, so it can’t be used elsewhere) and soft allocation (a preliminary hold). This stops double-booking and makes sure components always go to where they’ll create the most value.

- Kitting and Assembly Support: In electronics manufacturing, workers need to put components into a kit before they go to the production line. The warehouse management system takes care of this kitting process. It makes sure all the needed sub-components end up in the same group and get delivered together. This happens even when these parts show up in different, irregular shipments.

- Optimised Expedited Handling and Receiving

When parts need to arrive during a crisis, a new warehouse management system speeds up how we get and store things to focus on the most important materials:

- Cross-Docking Rules: The warehouse management system identifies urgent, pre-assigned parts as soon as they arrive. It sends them straight to where they’re shipping out or where they’re needed for production (cross-docking). This skips the storage step, saving hours or even days.

- Slotting Optimisation: The system can move critical parts near where they arrive or to a special high-priority area. This helps get them to the production line right away, temporarily overriding long-term slotting strategies.

- Audit Trail and Security

When dealing with valuable limited stock, a detailed record of all activities is essential to ensure security and meet compliance standards.

- Comprehensive Transaction Logs: The warehouse management system keeps track of every move, scan, and transaction linked to a numbered part, creating a complete record of its journey from arrival to use. This plays a key role in following regulations and preventing loss or theft.

- User and Access Control: The system puts in place strict security checks, making sure only staff with the right clearance can handle or move high-value materials.

The Strategic Outcome: Resilience and Agility

By using these cutting-edge warehouse management system tools, electronics firms turn their warehouse into a business advantage:

- Enhanced Flexibility: The power to allocate scarce resources as needed and handle urgent incoming shipments lets manufacturers pivot quickly in response to volatile supply signals. This cuts downtime on production lines worth millions.

- Maximised Output: Smart use of resources makes sure the few parts on hand go to finish the most valuable products first. This boosts income even when supplies are tight.

- Improved Customer Trust: Up-to-date, precise stock and resource data helps sales and support teams give realistic delivery dates. This keeps customers’ trust high even during worldwide shortages.

In the end, the semiconductor crisis showed that in complicated high-stakes supply chains, it’s crucial to manage inventory very precisely. The warehouse management system is a must-have tool that helps the electronics industry do more than just get by. It allows for detailed tracking, flexible allocation, and built-in automation. This gives companies the power to build truly robust supply chains.